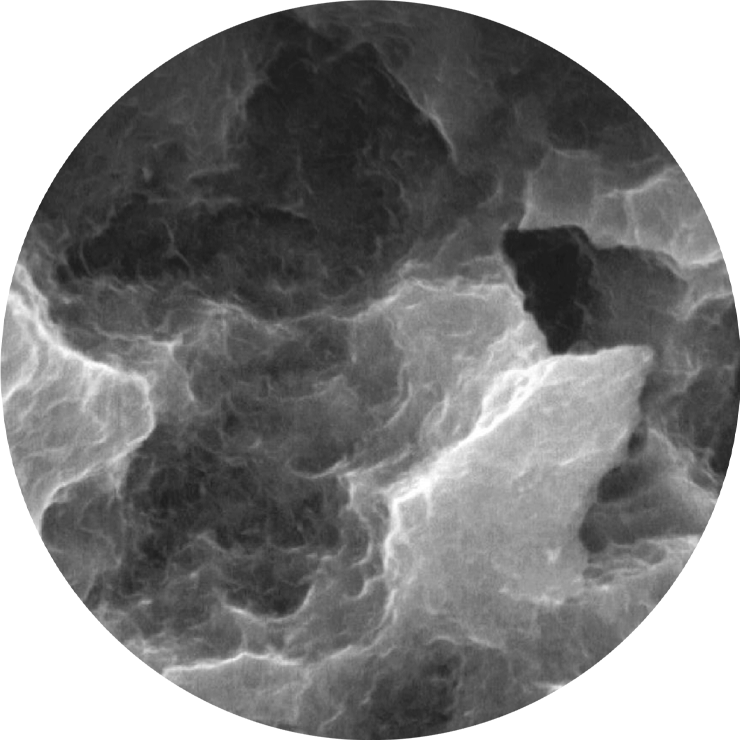

SA : Sand blasted with alumina and Acid etched surface

Apatite nano-coating is completely absorbed during the bone remodeling process and provides a long-term secondary stability on the SA surface.

Super hydrophilic SA surface suspended in calcium solution Same SA surface morphology Optimizing surface reaction with suspension in Calcium (CaCl2) solution Increased area of new bone formation due to excellent blood wettability Improved bone response at early ossess integration stage compared to standard SA surface Protein and cellular adhesion in Bone Response tripled compared to SA surfaces Initial cellular differentiation 19 percent (7 days) compared to SA surfaces Initial stability increased 34 percent compared to SA surfaces (RT at 4 weeks) Ossification rate SA surfaces (BIC at 4 weeks)

SA surface with premium low-crystalline nano-HA coating SA surface coated with HA (Ra 2.5 to 3.0/B) 10Onm ultra-thin HA coating Dual function between titanium and HA - HA is naturally absorbed during ossification Advantages of both SA and HA surfaces in Bone Response - SA's ability to maintain an optimal surface morphology - HA's ability to form high-quality starting bone even in a low-quality bone Ossification rate increased by 40 percent compared to SA surfaces (BIC) Unlike conventional surfaces HA surfaces can be applied to any bone quality

The new Hydrophilic properties promote this osseointegration in the early healing stages by providing more blood contact with the increased Sandblasted Acid-etched (SA) surface area, so it can start to clot faster. NH Surface The same clinically effective SA surface, but developed with a nanolayer bioabsorbable apatite with a super hydrophilic probe

Premium high crystalline HA coated surface 30 to 60 m thick high crystalline HA coating • HA coated (Ra 3.0 to 3.5arti) on an RBM surface - Over 98 percent high HA crystals Solved the problem with low crystalline HA absorption In-vitro & In-vivo Bone Response Excellent biocompatibility because HA very similar to real human bone weeks) Poor bone quality, suitable for extraction sites or immediate implant placement

Osstem Implant's KSⅢ SOI Implant surface coating material promises a shorter treatment time thanks to rapid blood clot formation and 2.4 times enhanced fatigue strength. According to Osstem Implant, the product is the first product in the world to apply a coating material to the implant surface. The SOI coating material is claimed to retain strong surface activation energy immediately after production and prevent the deposition of carbon compounds in air.